The Best Weight Distribution Hitch For Travel Trailers (Review)

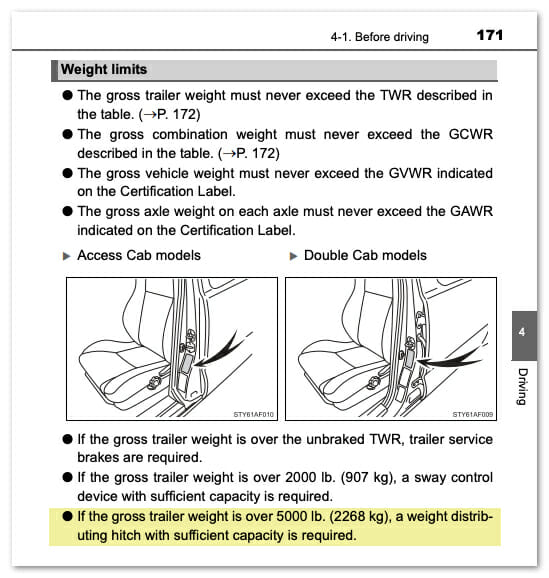

Weight distribution hitches are a lesser-known but incredibly useful accessory if you own a travel trailer. These hitches evenly distribute weight across the axles of your tow vehicle, protect it from uneven wear, and reduce trailer sway.

Put simply, weight distribution hitches make driving safer.

Most vehicle owner manuals recommend weight distribution hitches for heavy towable trailers, but many people don’t fully understand how they work.

In this article, we’re going to cover the ins and outs of weight distribution hitches and how to find the right one for your vehicle.

- 1,000 lb hitch

- Sway control

- Trunnion bar spring design

- What Is A Weight Distribution Hitch?

- How Does A Weight Distribution Hitch Work?

- Parts of a Weight Distribution Hitch

- Weight Distribution Hitches With A Sway Control Unit

- What Size Hitch To Get

- How To Install A Weight Distributing Hitch

- Finding The Best Weight Distribution Hitch: Reviews

- Best Budget Hitch

- Best Built-In Anti-Sway Hitch

- Best For Weight Distribution Hitch For Heavy Loads

- Best Hitch For Lightweight Trailers

- Frequently Asked Questions About Weight Distribution Hitches

What Is A Weight Distribution Hitch?

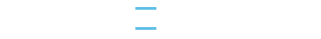

A weight distribution hitch acts as a lever that evenly distributes weight across all axles of your rig. It forces the trailer tongue to be more parallel with the road.

Without one, the weight of the trailer tongue weight bears down on the rear axle of your truck and stresses the shocks, struts, and tires. It also causes an upward lift on the front axle which can reduce traction, increase sway, and limit braking power.

Why You Might Need A Weight Distribution Hitch:

- If there is a noticeable sag in the rear axle of your tow vehicle

- Your trailer sways frequently or is hard to control

- You experience reduced traction or braking power

- Your headlights are pointing up instead of straight ahead

- The trailer weight (GTW) is over 50% of your tow vehicle weight (GVWR)

- You want to tow at maximum hitch capacity

Without A Weight Distribution Hitch You Risk:

- High pressure on the rear axle

- Worn out struts, tires, and shocks

- Decreased vehicle lifespan

- Upward lift on the front axle

- Reduced vehicle control

- Poor traction and braking power

- Unsafe amount of sway

Are Weight Distribution Hitches Required?

Weight distribution hitches are highly recommended if you plan on towing anything, regardless of its size. On many travel trailers, however, they are mandatory.

As a general rule of thumb, you should be outfitting your vehicle with a weight distribution hitch if your tow weighs 50% more than your vehicle does. More specifically, every tow vehicle comes with a max tow capacity that is located in the owner’s manual.

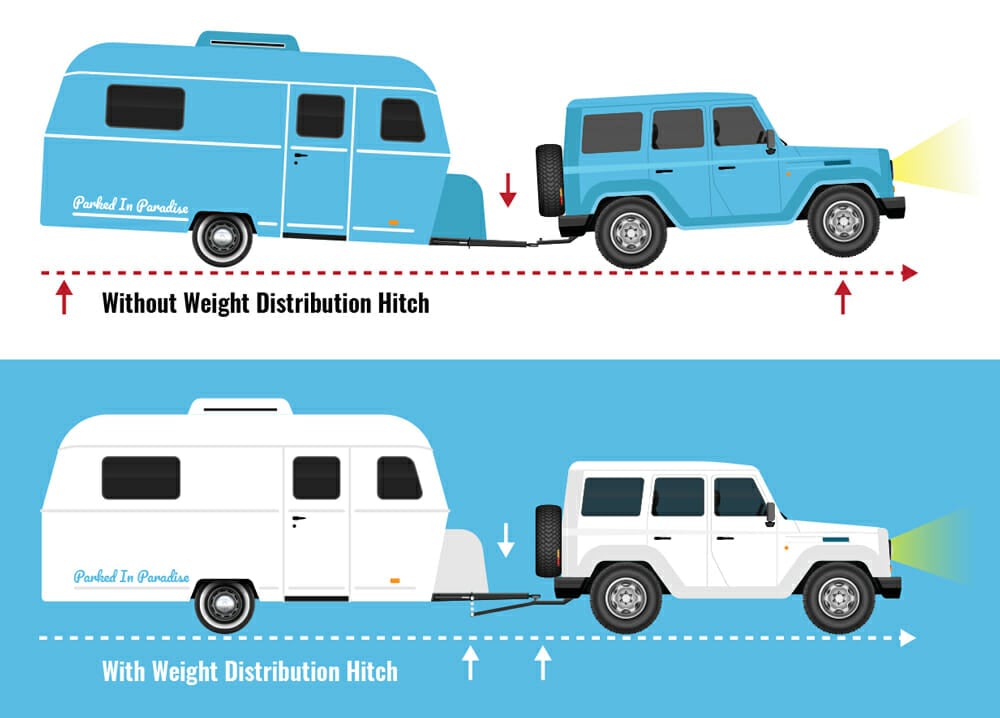

For example, the 2016 Toyota Tacoma owner’s manual states “If the gross trailer weight is over 5000 lb. (2258kg), a weight distributing hitch with sufficient capacity is required.”

It’s important to follow the owner’s manual because it will extend the life of your vehicle. A weight distributing hitch is less expensive than repairing a worn suspension system.

Not following the owner’s manual guidelines can also prohibit you from making insurance claims in some situations.

Can A Weight Distribution Hitch Increase Tow Capacity?

A weight distribution hitch won’t increase your tow capacity. Instead, it will allow you to safely use your hitch at maximum capacity. Without one, you risk damaging your vehicle.

Not All Vehicles Are Designed To Use A Weight-Distribution Hitch.

If the system is not mentioned in your owner’s manual, it likely cannot be used. Weight distribution systems can only be used with Class III, Class IV, and Class V hitch receivers.

Some weight distribution systems cannot be used on vehicles with surge brakes. These require a special type of hitch (with anti-sway control) because jerky movements can cause issues with the actuator on your tow vehicle.

- Cannot be used on Class I or Class II hitch receivers

- Special hitches are required for vehicles with surge brakes

Using A Weight Distribution Hitch with Suspension Air Bags:

Many modern trucks come with airbags to level out the vehicle, and people also often add them aftermarket. While these do solve some of the issues with towing, such as angled headlights and steering geometry, they do not negate the need for a weight distribution system.

With only airbags, you will still have an overloaded rear axle and poor traction and braking from the uneven distribution of weight.

How Does A Weight Distribution Hitch Work?

Parts of a Weight Distribution Hitch

There are five parts in a weight distributing hitch:

- Trailer hitch receiver

- Weight distribution shank

- Weight distribution head assembly

- Spring bars

- Frame brackets

1. Hitch Receiver

A trailer hitch receiver is attached to the frame of your tow vehicle. Weight distribution hitches work with standard receivers, but are only compatible with Class III, Class IV, and Class V ratings.

The hitch rating is typically found on a sticker on the hitch itself. Hitch ball ratings are normally stamped on top of the ball.

Typical hitch receiver classes:

| Hitch Class | Ball | Shank Length | Shank Diameter | Weight Capacity |

|---|---|---|---|---|

| Class I | 1-1/4" | 1-5/8" to 3" | 3/4" to 1" | Up to 2,000 |

| Class II | 1-1/4" | 1-5/8" to 3" | 3/4" to 1" | Up to 3,500 |

| Class III | 2" | 1-3/4" to 3" | 3/4" to 1-3/8" | Up to 8,000 |

| Class IV | 2" | 1-3/4" to 3" | 3/4" to 1-3/8" | Up to 10,000 |

| Class 5 - XD | 2" | 1-3/4" to 3" | 3/4" to 1-3/8" | 16,000 - 17,000 |

| Class 5 - CD | 2-1/2" | 3-1/4"+ | 2"+ | 18,000 - 20,000 |

Class III hitches are the most common on trucks. If your tow vehicle does not have the proper hitch ball receiver you can often install one yourself or take it to a dealer or shop to have it installed.

2. Weight Distribution Shank

2. Weight Distribution Shank

The shank attaches to the hitch receiver. It holds the assembly head and can be moved up or down depending on the height of your tow vehicle.

Most systems come with a shank included but you may need to purchase one separately if your tow vehicle has an excessive rise or drop.

3. Weight Distribution Head Assembly

3. Weight Distribution Head Assembly

The head assembly is the connection point between your shank and spring bars. These come in a variety of designs and also serve as a ball mount for the trailer and sway control attachment point for the spring bars.

4. Spring Bars

4. Spring Bars

Spring bars are the leverage system that evenly distributes weight. They come in variations on three designs:

- Round bar

- Trunnion bar

- Specialty bars

Round bar springs connect to the trailer frame brackets by dipping underneath and attaching with a clip. The tension bar also acts as the rotation point- a simple design with few parts. This design means they typically have poor ground clearance but they are the least expensive. These round bar hitches work best with lighter loads.

Trunnion bar springs are the most popular and best suited for heavier trailers. The straight bar design makes it easy to connect and they have higher ground clearance. The spring bars are connected to the head via bushing system making for a smoother ride but require slightly more maintenance.

Specialty bars are unique to the manufacturer. Some companies have created their own system like the Equal-i-zer and Husky Center Line system. These are typically variations on trunnion bars that reduce sway or give greater ground clearance depending on the design.

5. Frame Brackets

5. Frame Brackets

Frame brackets attach the spring bars to your trailer frame. The type of bracket you use can determine how much space is available for propane tanks or exterior gearboxes.

Snap up brackets connect to the spring bar via chain which is then “snapped up” to lock into place. You can make adjustments to the height by adding and removing links. This design is the fastest to adjust and easy to disconnect.

Bolt-on brackets use chains in the same way as snap-up brackets, but it’s harder to adjust the chain length once installed. These can be convenient if you don’t hitch and unhitch the trailer as frequently.

Sway control bracket systems do not use chains. Instead, these brackets are a solid design that captures the spring bars and allows horizontal movement to prevent sway. A pry bar and pin is required for installation. These are the most expensive systems but they will give you the smoothest ride.

Weight Distribution Hitches With A Sway Control Unit

Standalone weight distribution hitches do a good job of resisting trailer sway from friction points or improper loading. But because of the physics at work, they do not prevent sway caused by crosswinds.

A 35 mile per hour crosswind can apply nearly 3,500 pounds of force to the side of a trailer making it increasingly difficult to handle. If you want to prevent sway from crosswinds, you need to purchase an anti-sway hitch.

There are two ways to combat this sway paired with a hitch. With a built-in system and an add-on sway control unit.

Anti-sway hitches tend to give you a smoother driving experience because they are designed to work well with all of the other components. But if you already have a hitch without sway control, an add-on system might be preferable.

Add-on Anti-Sway Units

Friction bars are the most basic form of sway control. They are inexpensive, and ideal for compact or light loads. A friction bar is an add-on component that attaches to the weight distribution hitch.

As the trailer begins to sway, a bar telescopes in and out, rubbing against friction pads. This reduces the speed of the side-to-side movement that can happen in your trailer. You adjust the amount of friction in the arm and install one or two depending on your trailer load and length.

Although friction bars work well for smaller loads, they have a number of downsides. For one, these do not work in slippery road conditions (wet, gravel, ice, etc). In fact, they need to be disconnected in these situations which can be an inconvenience and difficult to remember.

Friction also bars need to be disconnected when backing up or taking tight turns. They are not compatible with trailer surge brake systems because the friction in the bar messes with the actuator.

- Recommended for lightweight campers under 24 feet

Built-in Anti-Sway Control Bars

There are three main types of sway control units. These built-in systems reduce the friction points in the hitch resulting in a smoother ride. 2-point and 4-point systems work with vehicles that have surge brakes.

Two-point control: These systems use bolt-on brackets rather than chains to attach to the trailer frame. The tension bar rests against these brackets (or a friction pad on them), free to slide back and forth as the trailer turns.

This friction at the two points reduces sway, and because the bars have lots of lateral movement they do not interfere with surge brake systems.

- Recommended for trailers 24-30 feet

- Compatible with surge brakes

Four-point control: In addition to adding friction where the bars contact the trailer, these systems add tension where the bars contact the hitch head. This creates more adjustability, especially for heavier and longer trailers.

- Recommended for trailers over 30 feet long

- Compatible with surge brakes

Dual-cam stabilizers: The most expensive sway control unit is hitching with dual-cam stabilizers. In this design, separate spring bars with curved ends are used to prevent sway before it starts–there are no chains involved. These give you the best control but are also the most expensive and cannot be used with surge brakes.

- Recommended for trailers over 30 feet long

Electric Stabilizers

Some trailers come with electronic brakes that function when they sense the signal from the trailer brake wiring.

This type of anti-sway hitch can also be added aftermarket if you already have surge brakes. In contrast, surge brakes are entirely mechanical devices that simply apply brake pressure when your trailer is traveling faster than your tow vehicle (surging against it).

A side benefit of the electronic systems is that the brakes can be used to limit sway. These systems work with or without a weight distribution hitch.

You can buy a stabilizer that applies brakes to either side of your trailer depending on which way it is swaying and can be installed in line with an electronic braking system.

Electronic brake stabilizers are ideal for tow vehicles that cannot accept a weight-distribution hitch.

Backing Up With Anti-Sway Control

You can back up with a weight-distribution hitch installed, but you need to disconnect friction control bars. 2-point, 4-point, and dual-cam stabilizers allow you to back up a towable trailer.

What Size Hitch To Get

Once you’ve decided on which type of weight distribution hitch to get, it’s important to pick out the appropriate size. First and foremost, make sure your tow vehicle is capable of towing the trailer you’ve selected.

CampingWorld.com has tow compatibility calculator where you can input the tow vehicle and receive a weight capacity recommendation.

The two numbers you need to know when picking out a hitch are:

- Gross trailer weight including all liquids and gear

- Trailer tongue weight

The most accessible method to weigh your trailer is at a truck weigh station. The trailer tongue should weigh between 10-15% of the total trailer weight.

The COOLEST way to get your trailer weight is to spring for a Curt BetterWeigh towing scale. This is a little device that plugs into your truck.

It then uses the truck’s computer to measure transmission slip as you’re driving and from that, it can tell how much weight you are hauling, along with tongue weight and a few other data points. Then you just read it all on your smartphone.

Hitch size is based on the trailer tongue weight.

Choosing a hitch that is too large for your trailer can make the ride bumpier, while hitches that are too small won’t work effectively. You should choose a hitch where the tongue weight rating lies somewhere in the middle.

Remember to load your trailer with 60% of the weight in front of the rear trailer axle and 40% behind for safe towing.

How To Install A Weight Distributing Hitch

Finding The Best Weight Distribution Hitch: Reviews

Best Budget Hitch

EAZ-Lift 1,000 lbs Elite Weight Distribution Kit

If you’re looking for a weight distributing hitch on a budget, we like the EAZ-lift weight distribution hitch system. These round bar hitches have the same great features of more elaborate products but at a more reasonable price.

The hitch reliably increases your stability and safety on the road. The lower price does not make it less applicable, it just has a few more inconveniences. If you do not have surge brakes, we recommend the kit shown with the friction bar; just remember to disconnect in slippery conditions or when reversing.

- 1,000-pound weight distribution hitch

- Sway control

- Round bar spring design

- 1,000 lb hitch

- Sway control

- Trunnion bar spring design

Best Built-In Anti-Sway Hitch

CURT TruTrack with Sway Control

Curt has great customer support videos and is a well-known brand in the industry. Because of their broad support network and dependability, they are a no brainer for most applications. Sight unseen, we generally recommend their products over others. This two-point trunion bar hitch has detailed angle adjustments to get your load and tension correct and riding well. It can support moderate loads and works backing up and with surge brakes.

- 1,000-pound weight distribution hitch

- Sway control

- Trunnion bar spring design

Best For Weight Distribution Hitch For Heavy Loads

Equal-i-zer Sway Control Hitch

If you’ve got a large trailer, the Their Equal-i-zer system is our top choice. This hitch uses 4-point friction to allow for maximum sway control with heavy loads (up to 14,000lb tow weight!)

- 1,400-pound weight distribution hitch

- 4-point Sway control

- Trunnion bar spring design

Best Hitch For Lightweight Trailers

Husky Center Line

When it comes to lighter trailers (under 8,000 pounds) the Husky Center Line is our favorite pick. This hitch is quiet and extremely easy to install and remove. That means it’s faster to hitch up and get moving once your camping trip comes to an end.

- 800-pound weight distribution hitch

- Sway control

- Quiet, fast install

Frequently Asked Questions About Weight Distribution Hitches

Is a weight distribution hitch worth it?

Yes, weight distributing hitches make towing a trailer safer. They reduce trailer sway, give you more traction, and increase braking power.

Does a lightweight trailer need a weight distribution hitch?

If you notice your trailer sagging, swaying frequently, or reducing friction or braking power, then you should get a weight distribution hitch. These problems can occur as little as 3,000 pounds.

How much more weight can you pull with a weight distribution hitch?

A weight distribution hitch does not increase your tow capacity. Instead, it will allow you to safely use your hitch at maximum capacity.

Can you back up with a weight distribution hitch?

Many weight distribution hitches have no backup restrictions, but all of them will limit your turning radius. Some hitches with add-on sway control bars are not designed for backing up.

Weight distribution hitches are a necessary accessory if you’re towing a large travel trailer. These units will reduce trailer sway, give your vehicle more traction, and most importantly: make driving safer.

2. Weight Distribution Shank

2. Weight Distribution Shank 3. Weight Distribution Head Assembly

3. Weight Distribution Head Assembly 4. Spring Bars

4. Spring Bars 5. Frame Brackets

5. Frame Brackets

This Post Has 0 Comments