RV and Camper Van Solar Calculator

How many solar panels do you need in an RV or camper van conversion? Simply fill out the calculator below to find out.

This solar calculator is meant for camper vans, RV motorhomes, and small off-grid solar systems. The goal is to help you find the correct size solar panel, charge controller, inverter, and battery bank for your DIY build.

We also include links to solar wiring diagrams so you can fully connect your own system. Let’s get started!

Video tutorial

Calculator

Watt Calculator (Amps x Volts = Watts)

List Your Devices

Enter number of Watts each device uses and your estimated max hours of use per day. Click the to add a new row. Click the to delete a row. Select whether your device is DC powered or will be using an AC inverter.

Estimated Watt Hours

This is the maximum power you will expect to use on any given day. If using heaters and fans, it is helpful to do a calculation for a winter month and a summer month (including sun hours below) and use the larger of the two.

Daily Power Usage

0Wh

12V Battery Size

Battery Type

Select whether or not you will be using a Lead-Acid (AGM) or a Lithium battery chemistry. AGM batteries wear out quickly if you use more than 50% of their charge, so they require a larger battery bank to compensate.

0Ah

Solar Panel Size

Recommended Min Solar Watts

This is the fewest recommended solar power based on the daily power usage and battery size. Check out the FAQ for info on charging while driving and upgrading panels. PWM charge controllers are much cheaper but less efficient than MPPT technology, so they take more minimum solar watts to charge the batteries.

0W

Charge Controller Size

Charge Controller Size

This is based on your solar panel wattage. It is the smallest size charge controller that you will want to use. Going smaller will be giving up power from your panels. Remember to check the requirements of your specific charge controller to make sure it will work with your panels before buying it.

0A

Inverter Size

Recommended Inverter Size

This is based on your battery size and is a recommendation of max discharge rate from your devices. If it is significantly lower than your needs, consider getting a larger battery bank to compensate. See the FAQ for further reading on running a larger inverter.

0W

Solar System Results

0

12V Battery

0

Min Solar

0

Charge Controller

0

Inverter

How to use the solar calculator FAQ

- Make a list of your devices

- Enter the watts for each device

- Enter your estimated hours of use

- Select whether it is an AC or DC powered (AC uses an inverter)

- Choose which battery type you want to use

- Choose your charge controller type

- Enter your estimated sun hours (direct sunlight you expect on the panels)

How do I find the Watts of my device?

In most cases you can find the Watts listed online, in the owner’s manual, or on the product itself. In some cases, a product will list Amps and Volts instead.

Remember: Amps*Volts=Watts

If you still don’t know how to find these numbers, read our article on calculating your power usage for each electronic device for some tips and real-world examples.

What if I know my total Wh and just want to get calculations for components?

You can enter it as one component line. Type in your total Wh for “Watts” and 1 for “Hour” and the rest of the solar calculator will function as normal.

Why is my solar system so big?

You are probably still planning to use power like you would in a house. Living in a van or RV requires cutting down on unnecessary electronics as much as possible.

The size of your system is also directly related to cost. Here are some tips to cut back on electronic use.

- Aim to use as many 12v DC powered electrics as possible

- Cook efficiently – fuels like propane and butane will make your system smaller than cooking with electricity. Try to cut back on induction burners, coffee makers, crockpots and other high-energy devices

- Make sure you have the correct hours listed for your refrigerator and electronics. Your fridge will not be running 24 hours per day. In cold weather, the compressor in a fridge may only be running 2-4 hours per day, despite the fridge being on the whole time. In hot climates it may be running as many as 8-16 hours. Similar to laptops and induction burners; they are not usually running at their max rated watts.

- Look back at your components. See what is drawing the most power and look at ways to reduce or eliminate it.

How much does AC vs DC power change the numbers?

We based our calculations on a 10% efficiency loss that occurs when using an AC inverter.

What is the difference between AGM, FLA and Lithium Batteries?

There are many differences between these batteries. But the main difference (as it relates to this calculator) is the depth of discharge – or DOD.

A lithium battery can be safely discharged up to 90% without shortening its lifespan. AGM and FLA batteries should only be discharged up to 50%. The less you discharge per cycle, the longer the batteries will last.

Because of these discharge rates, you will need a larger AGM or FLA battery for your system than you would with Lithium. You can read more about batteries here.

Can I also charge batteries using my vehicle?

Yes! Absolutely, and it is recommended to supplement any solar system unless you plan on driving infrequently.

The best option is a battery to battery charger, many of which double as a solar charge controller. A cheaper option is to go with a battery isolator.

What is the difference between a PWM and MPPT charge controller?

The actionable difference lies in efficiency. A PWM controller uses less complicated and less efficient technology. With that said, for smaller 12V systems, it is often advisable to get a PWM controller and more solar panels get more bang for your buck.

We recommend reading our post on charge controllers for more information.

Can I get a bigger charge controller and add more solar panels later?

Yes, this component can benefit from upsizing if you’re not sure if you’ll need more solar or not.

With that said, it’s usually a lot of work to add more panels on the road so we like doing them all at once. Check out our article on charge controllers for more in-depth info.

What number should I use for Sun Hours?

The amount of power you get from the sun is determined by how much direct sunlight your panels get. If you are in the sun more often, then you need fewer panels to charge your batteries.

Basing your calculations at 4 sun hours is a good conservative estimate for most full time travelers varying lifestyles. If you have tilt-mounted panels or are mostly living in a sunny place like Arizona, then you might need less solar watts because you’ll be getting 5-8 hours of direct sunlight.

You are welcome to play around with this number, and even combine it with your winter/summer total watts to see what a comfortable system size is for you.

Do I need an inverter?

No! If you don’t have any household (AC) electronics you do not need an inverter, saving some money and efficiency.

How much lower than the recommended inverter size should I go?

As a general rule, smaller inverters are more efficient. If the biggest item you will be running is a 150W laptop, then getting a 1000W inverter is a waste of money and efficiency.

Go with the smallest inverter that you will need with a bit of wiggle room. In this example, a 200W or 300W inverter would be fine for a 150W laptop.

Why is my inverter sized so small? I see other people recommend 1000W+ inverters all the time with a small battery bank.

Battery life is affected by how quickly you are using power. This is relative to how much total capacity the battery has, so larger batteries can discharge more quickly (hence a larger inverter).

If you occasionally are using more power – such as a hair drier for a few minutes once a week – then you won’t be doing too much damage to your batteries. But if you’re twice daily using an 1800W induction burner, you’ll want a large battery bank to handle the heavy loads or else will be replacing your expensive batteries quickly.

Read our article on inverters for more information. As a side note, the discharge capabilities of lithium batteries are significantly better than those of AGM or FLA.

Why didn’t you list ALL of the components I need? Wires, fuses, ect.

Your wire size is going to vary greatly depending on how far you are running them. Read our wiring guides for more details on how to size your specific system.

It is difficult to predict how much wiring each different van build will have and the lengths needed, and we don’t want to have you ordering things that you don’t need.

Solar power looks dangerous and scary – what do I do?

If electricity is intimidating to you, we recommend looking at solar powered generators which are plug and play devices that require little-to-no wiring. These are safe for anyone to use. The only difference is that you’ll be paying extra for the privilege.

Consider purchasing an RV solar panel kit which comes with compatible parts that are already designed and sized to work together. This takes a lot of the guess-work out of buying each item separately.

Ok I got everything, now how do I put it all together?

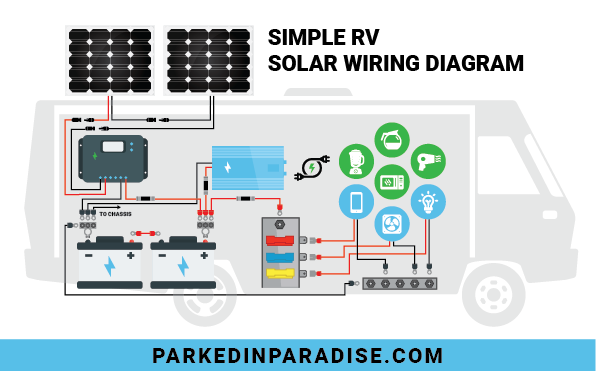

Awesome! Click on the solar panel wiring diagram below closest to your numbers and get started! If you want more information on electricity, head over to our electrical home page.

Solar Panel Wiring Diagrams

Use these solar panel wiring diagrams for information on putting together your DIY solar panel system. These include all of the components, fuse and wiring sizes, and directions to get started.

Helpful information on choosing components

- Camper van solar panels

- Solar panel kits for an RV

- Solar charge controllers

- Battery banks for solar storage

- 12V inverters

- Converters, inverters, and inverter/chargers for RVs

- Solar generators

- How to install a battery monitor

Battery charging tutorials

In a camper van – or any vehicle where you drive frequently, you can supplement your solar system by charging your battery bank using your car’s alternator. These are the most common ways to do it:

Visit our Electricity Main Page to see all of our camper van electrical posts. There is further reading on all parts of the system, extras to install tips and advice on all things electric!

Thank you for such a well laid out info site, W/ LINKS! I’m using 2- 100 Ah AGM battery’s that I’ve wired together in paralell w/ 2, 8 gauge cables. I’m WAY over powered as I only use 3 low wattage fans and recharge my tablet and phone. I recharge with a NOCO GENIUS that i hook up and plug in at work, which is an amenity they allow, a grace of God really. I’m looking to eventually hook up a refigerator/ freezer, around 25 quarts? Hence the large batts. I reside in my van all year when not at my sister’s down the street. I’m able to save alot of money on rent this way, and thanks to being knowledgeable about electricity/electronics, I’m very comfortable.

Great article Very good explanation of solar basics. I would like to know how I add alternator charging as I drive as well as shore power charging at RV parks. Also any tips on mounting ridged palels to roof. Is some type of rubber flex system a good idea?

On-grid solar system involves solar panels and inverter. Used to reduce electricity bill. No backup as there is no battery.

Hi power magnets with screw in eye bolts worked well for me

This is excellent. Thanks for doing all the workings out for us!

Thank you so much!

I love a good spreadsheet/ calculator and was having trouble pinning down what i need for my campervan! You have saved me alot of effort ?

Hi can anyone tell me where I can buy a cassette toilet /washand basin/shower unit complete for the back of a sprinter. Regards, Get.

Hey! We’ve got a post on cassette toilets here: https://www.parkedinparadise.com/cassette-toilet/ and a post on portable showers here: https://www.parkedinparadise.com/portable-propane-water-heater/

Hope that helps!

This website is fantastic! Thank you so much!

How to calculate slid fan load wich have 3 setting for example 1,2,3

Hey Goizah, that depends a lot on the type of fan you’re using. We have a chart in our vent fan article (https://www.parkedinparadise.com/best-roof-vent/) which shows the amperage draw for the Maxxfan and Fantastic Fan at each setting. You might find that helpful.

I plan on building a skoolie in the future, and am toying with the idea of running 24v instead of 12v. This is a helpful starting point for me to figure out what I need. If I use this to calculate, would I just halve the Ah needed for the battery for a 24v setup?

In your 400W diagram, you have the following battery recommendations:

200Ah (x2) Battery (AGM option)

100Ah (x1) Battery (Lithium option)

Would you not want 200Ah with the lithium option? I know they can be discharged more than their AGM counterparts, but that still seems rather low. Thoughts?

And thanks for all the great detail in your excellent guides!

Hey Ross, good catch! We must have missed that while we were making our various posts.

Your calculator is GREAT! – But I do have a question about the panel diagram. If each panel is 12V – why would they be wired in SERIES to obtain increased wattage (but not voltage). If 300 watt diag (for example) you would have 12v X 3 = 36 volts. Going into a solar controller rated at 12v. Am I missing anything on this basic “volts in series = all volts sum”? Thanks! Great site!

Andy-

Thanks for the comment, it shows you understand the Amps x Volts = Watts equation. I think you meant increased amperage (not voltage), but I get the general question and it is a good one to ask! The voltage of the solar controller is the rated output of the controller. The input depends on many variables but is generally always higher. “12V” solar panels typically output between 18-22V, which fluctuates based on external factors (sun, temperature, angle, etc). The CC takes that fluctuating energy and turns it into a tame charge voltage that the batteries can handle. For a 12V battery bank, this will be between 13.5V and 14.8V depending on where the batteries are at in the charge cycle.

So, with that said, an MPPT charge controller has the ability to “convert” the extra voltage above that charge level to amperage, thus using as much energy as possible for charging the batteries. The charge controller can do this with 18V or 24V or 36V or a range of voltage inputs (depending on the controller) and use it to charge 12V batteries. Meaning that you get the same amount of theoretical power from two 100W panels in series as you do from two 100W panels in parallel when using an MPPT controller. I say theoretical because in many ways wiring panels in series is slightly more efficient than wiring them in parallel. There is more detail in this in our charge controller article if you want to know. Certain circumstances benefit from wiring in parallel, but our default is to wire in series. Hope this helps!

Thanks Ian, I did not know that the CC would step down in those cases. So in my application, I have a 12V motor that will use 12 amps (144 watts) for 8-10 hours a day. Using your calculator, rounding up with worst case, I will need a 12v 200 ah battery and 300 watts of panels. So in this case, 100 watt, 12V panels in parallel will give: 12 v (12 to 18v) and 300 watts out total. But you suggest in series I’ll then have 36v (12+12+12v) and still 300 watts out? I would then use the CC to step to the 12v needed to charge the battery. In series wouldn’t the CC stepping down use some of the potential power? – I will check out your charge control article next. Thanks for your input!!

do you have any information for using three inputs? Solar, Alternator and shore power. Also, is there a good way to get power use estiments for devices? example: looking at a microwave that says it uses 720 watts. Im guessing thats for the durration of use? so I use it for 10 minutes, thats 0.6 of an hour so 720/0.6 = wH of use? Or a refrigerator that cycles during the day.

Im in the planning pase as you may have guessed. Thanks for your work, its the best place for information I have found.

this is awesome and very helpful. thank you!

Umm… New guy here, but I thought I might point out an error. On the drawing for the Large Systems: Wiring Diagram (AGM Batteries), you will want to correct the battery wiring so nobody catches a face-full of acid. You have two batteries in series (24v) and they are in parallel with a single battery (12v.) And those are in series with the first battery. Oops…

I plan on powering my pop-up Skamper using a 40A MMPT controller, and a 1000W Pure Sine Wave inverter. I’m purchasing a single 12V/100W panel and a single 50Ah AGM just to get started. With the beefy internals, I figure, I can add more panels and batteries later. This is my first solar project. Just want to charge some phones at night and make coffee in the morning. the system can recharge the batteries the rest of the day.

Similar thoughts… but I’m struggling with the charge controller sizing myself… given other elements are fixed (due to size).

I’m running four 100 watt panels… 2 series of 2 (alternating in my rooftop real estate – a 5ft x 7ft trailer) combined in parallel into the charge controller.

At first I was gonna run 2 battery banks (as I don’t have same batteries/ ages/use cases, types) but this build is turning into a nightmare (even though I can isolate them for charging – but only PWN chargers can I find with dual battery outputs that never charge simultaneously – bad for different batteries).

Now I’m thinking scrap the [free] group 27 deep cycle battery with ~80 amp-hours capacity and just going with 3 (maybe 4) 35 amp-hour AGM in parallel (again a space issue – fitting “short” batteries under the frame).

At first I thought 20 amp CC was good enough 18 volts x 2 = 36 volts (series) and 5.5 amps x 2 = 11 amps (parallel) into the CC… but everywhere I’m reading seems to indicate I’ll somehow be shedding massive volts down to 14 +/- 0.5

Any of my wire runs are no more than 6-8 ft… so #12 AWG should be fine for wiring, but I’m way confused on this current/amp boost that will happen between CC and batteries in a 12 volt system???

Is a 20 amp CC rated for input or output???

Hans,

In you situation, you would indeed be dropping significant voltage because of your choice of PWM controller. PWM controllers don’t have the ability to “step down” voltage, they essentially just throw it away. So, you have two choices: 1) wire your panels all in parallel instead of 2S2P. This would make your input at 18V and you would be getting more advantage of a PWM controller without loosing significant power. You would need about a 30A PWM in this case, but I think it is a good option for your scenario and budget. 2) Get a MPPT charge controller. This is the more expensive option, but allows more flexibility in input wiring.

The 20amp is the output rating for a CC.

For batteries, my choice would be to scrap the old ones. It’s possible that it would work out, but there is a significant chance that they will end up costing you more in the long run and cause frustration on the road. Make sure you wire your batteries in a parallel string that maximizes their lifespan: http://www.smartgauge.co.uk/batt_con.html

I am looking to do the 400 watt hook up, I understand how each component is to be placed but what I am having trouble with is the size of wire to use from the solar panels to the Battery bank, and then to the fuse block to run for the lighting and plugs to power some of the equipment like the cell phone and laptop. so is there a book and or a diagram that helps explain this from each unit.

My camper is stationary (used as a permanent camp) and off grid. I am looking at getting Solar and all of the installs suggest connecting to the existing wiring inside the camper. Is there any reason I cannot simply connect the solar to batteries outside the camper, and connect the Shoreline to the inverter? Seems to me that this would not only run the A.C units but would also charge the batteries inside the trailers. Is there any down side to this approach?

Excellent page guys, nice work. I wish I had come across this 2 years ago when I was building out my van and trying to figure out all this stuff. 2 years later I’ve learned a lot too!

I’m resizing now due to an oversight in my original plans. Don’t underestimate cloudy days! I live in CO and travel a lot West and South, I sized expecting nearly unlimited sunny days. But alas, after 2 days of clouds I’m struggling with my power consumption. Despite having 400 watts of panels on the roof, on a cloudy day I’m lucky to make 4 amps, less if the clouds are extra thick and nothing if raining.

I’m looking now to drop $2,500 on lithium to solve my problems 8-D I’m thinking about 300 AH of lithium is enough to get me through several days of making no or little power. And on days I do get it, I can put out my 5th portable panel and dump 20 AMPS an hour into the lithium’s when I can. It’s just so crazy expensive.

I use a good bit of power because I work from my van. So I use about 8 amps to run my laptop, second monitor and play music. The refer uses 5 amps, but cycles hourly, so guessing it’s using 2.5 amps an hour, depending on temperature of the van of course. Not to mention fans and other incidentals, and losses throughout the system.

Now I’m wondering, and what brought me to your site, is if there’s a benefit from multiple batteries? I can get the amps I want using 1, 2, 3, or more batteries. Thinking if I have just 1 and it stops working for some reason, then I have no reserve. If I have 3 and one stops working, I can re-wire in the field with the 2 remaining? Are there losses with multiple batteries?

I know with lead batteries, you’re supposed to use the same year, etc, I don’t know if that’s true for Lithium. For instance, can I buy 2 lithium batteries now and add more a few years down the road?

Sadly I’ll be ditching my $800 worth of 200 AH AGM batteries for lithium.

First, Thanks for sharing your knowledge. My question is the AC charger for an electronic device has 0.50A input and 1.67A or 2.0A output, do I use the input or output number for solar sizing?

Thanks

Really nice and simple calculator but limited to summer use, what I need to know is what kind of drop off would there be in winter, I need this so I can build a system for use 365 days of the year.

Hey Andy, for winter camping, adjust the list of devices and number of sun hours. For example: a refrigerator might be running 8 hrs/day in the summer, but only 4 hrs/day in the winter. If you’re running things like an electric heater, include that in your list of devices for winter.

Winter sun hours will be less than summer ones. You can put your location in a site like this: https://unboundsolar.com/solar-information/sun-hours-us-map to find the average sun hours per day. If you’re changing locations frequently, we like to use 3.5-4.5 sun hours for winter.

We recommend calculating both your summer and winter numbers. Then build your system to the largest number.

I’m concerned about the solar_factor variable you use to compute the required power output from the solar panels. If I am consuming a certain amount of power throughout the day, then the solar panels alone must be able to source that power. So why is solar_factor greater than 1? Why should it be as high as 1.2 for a PWM controller or 1.3 for an MPPT controller?

I understand possibly amortizing varying power usage over multiple days, but then you would need a larger battery system to support that.

Is it to account for solar panel power output during sunrise and sunset? If so, that should be a constant increase instead of a multiplier.

Ned,

You’re looking at the formulas, I assume?

These calculations are mitigating the inefficiencies of the solar system. I haven’t pulled up the formula to look at the function (I don’t read the script very well, but I do triple check that all of the math is correct). Remember that the calculator is determining what system size that you need based on your inputs (not how much output you will get from an existing system). A 100W solar panel plugged into a PWM controller will not be putting in 100W of power to your batteries. Due to the controller needing to adjust voltage to charge properly, some power is lost to the system. So we mitigate for that effect by estimating more solar. For instance, if you need 150W of power, but your system is only 75% efficient, then you would need 200W of panels to get 150W into the batteries. The numbers you’re looking at function in this purpose. I’m not sure exactly where in the formula the 1.2 and 1.3 come in the way we set up the calculator (it was awhile ago), but you’ll notice that with an MPPT system, you need less wattage in panels than a PWM one because MPPT controllers are more efficient.

If you want me to dig up the formula, let me know, it’ll just take some effort on my part.

Thanks so much for the thorough diagrams!

I have a setup that’s going to be all DC, no AC required. I have the same solar charge controller shown in your diagram, but I can’t find the specs for it. You show the loads directly tied to the battery. Can you confirm that the wiring can be setup so that the fuse block / load can be wired directly through the controller?

Katie-

Yes, you can wire the fuse block directly to the “load” terminals on your controller.

If you’re asking if you can do this without a battery, then the answer is no. You still need the CC wired to a battery through the battery terminals. The battery is essential for the system, not just to store energy but to create a balanced energy source (rather than the erratic energy that comes from the sun). The “load” terminals on the CC are in fact pulling energy from the battery, not the solar panels.

Thanks for the great article. I am planning to use 2 100W panels.

I also have the same charge controller as in your diagram (30A). I purchased 10 gauge extension cables but the wire is so thick that it does not fit into the holes on the bottom of the charge controller. I have looked for 10 gauge ends to crimp onto the end of wire that will fit into the holes but have had no luck. All I’ve been able to find are rings, spades or slabs. Suggestions?

Also, for the 3 fuses above the positive battery terminal, I purchased 40 amp fuses. Is this correct?

Thanks again.

Awesome write up. Very informative, thanks for sharing!

all I want to do is run a 12″ inch 120v desk fan when I go to sleep in my minivan. I was using a spare 12v car battery with an inverter but it only lasts 2 hours or less before the battery dies. Then I start sweating like a dog. What can I do to keep that fan running for at least 7 hours? I can’t connect the inverter to the van’s battery for obvious reasons. Thank you for any help.

Posted this on wrong Blog entry. I meant to post it here.

In your controller diagram you show the BATT as being the far right terminals of the PMW controller. In 97% of the 10-20 amp PMW controllers I have seen, the BATT is the center set and the LOAD is the far right. You should label your ports on the controller diagram so someone doesn’t put the battery in the LOAD port on the common Chinese controller. (IMO)

I used your Calculator and was wondering on the Solar Panels could i use a 360 Panel instead of 3- 100 Watt panels?

Solar System

Lithium Battery 135Ah (x2)

Solar 260W (360W)

Charge Controller 30A (40A)

Inverter 1100W (1200W)

This really helped me calculate what setup would be needed.

I have been really strugling to identify this

Thanks so much!!!

I got :

1- 40 watts solar panel

1- 100 watts solar panel

1- 30 amps chg controller 12v

3- deep cycle batteries 12v

1- inverter.

I’d like to have all of those hookked up so I have electricity reserve and taking advantage of both panels.

I plan to plug batteries in parallel to keep 12v but augmenting supply but NOT SURE about the panels tho. They are Listed at 21.5 v but always have worked but should they be in series, parallel ? I donno

Any advice would be appreciated

Thanks

Simon

Regardless of the solar panel you go with, how much energy it produces is dependent on how much sunlight reaches the panels. Whether it’s clouds in the sky that block sunlight from the surface or snow or dust that cover the solar panels, the weather is a big factor in that.

thank you so much for sharing this valuable information

We Are Very thankful because you wrote this Article for us.

Thanks For sharing this valuable content with us.

Hi folks,

I’m renovating/redesigning the interior of my 96 Thor Pinnacle camper from scratch.

I’m using lightweight materials, multi-purpose furniture like a Murphy bed/desk.

Designed a circulating shower. I’m installing energy-efficient appliances.

No propane a normal household mini fridge and freezer, infrared floor heating, no furnace. Induction cooking …

I made a rough calculation (can’t upload a pic or pdf)and I need about 21 kwh 300 Amps to power all this.

I’m planning to install 6 x 200w flexible mono ETFE solar panels and 3 200Ah LiFePO4 Lithium Batteries.

I know that the lifespan of flexible solar panels is not that great but cutting the weight is something that I consider.

I’m planning to travel from May till September around the Mediterranean.

So my question is, is my solar setup enough or overkill ?

I like the ease of your calc but when i enter my induction stove (1800w), AC, use for 0.5hr as my sole/total elect load, the calc recommends an inverter size of 800w…

That doesn’t right, does it?